Silk screen lanyard process

There are many kinds of lanyard processes, such as: silk screen printing, thermal transfer (sublimation), glue transfer, pad printing, jacquard, embroidery, woven label; luminous, reflective, flashing, laser; three-dimensional, foaming, etc. What is each process like? Today we are going to talk about silk screen printing.

Silk screen printing is a quicker way to make printing lanyards, but its process is not as simple as you think. Its working principle is to use the basic principle that the mesh of the graphic part of the screen printing plate is transparent to the ink, and the mesh of the non-graphic part is not permeable to the ink. When printing, pour ink on one end of the screen printing plate, apply a certain pressure to the ink part of the screen printing plate with a scraper, and move to the other end of the screen printing plate at the same time. The ink is squeezed onto the substrate by the scraper from the mesh of the graphic part during the movement. Due to the viscosity of the ink, the imprint is fixed within a certain range. During the printing process, the squeegee is always in line contact with the screen printing plate and the substrate, and the contact line moves with the movement of the squeegee. A certain gap is maintained between them, so that the screen printing plate during printing generates a reaction force to the squeegee through its own tension. This reaction force is called rebound force. Due to the effect of resilience, the screen printing plate and the substrate are only in moving line contact, while other parts of the screen printing plate and the substrate are separated. The ink and the screen are broken, which ensures the printing dimensional accuracy and avoids smudging the substrate. When the squeegee scrapes the entire layout and lifts, the screen printing plate is also lifted, and the ink is gently scraped back to the original position. So far it is a printing trip.

Direct printing process: stretched web - degreasing - drying - peeling off film base - exposure - developing - drying - revision - screen sealing

Indirect printing process: stretched web - degreasing - drying - indirect film - exposure - hardening - developing - laminating - drying - revision - sealing

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

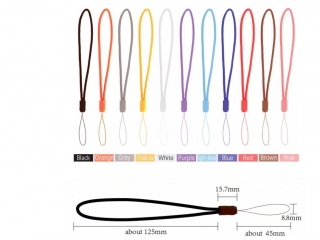

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more