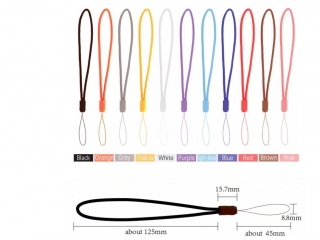

The advantages of using nylon to make a lanyard

In today's society, nylon has long been a commonly used material in the webbing part of lanyard products. Nylon lanyard made of nylon material is environmentally friendly and beautiful. Due to its fine and smooth surface characteristics, it is very suitable for silk screen LOGO processing on the surface. Generally, the nylon used in nylon lanyard products has higher purity, and some are mixed with other types of yarn, such as polyester.

Nylon, near the flame, quickly curls and melts into a white gel. It melts and drops and bubbles in the flame. There is no flame when burning. It is difficult to continue burning away from the flame. It emits a celery smell. The light brown melt is not easy to grind after cooling. . Polyester is easy to ignite, and it melts when it is near the flame. When it burns, it emits black smoke while melting. It shows a yellow flame and emits an aromatic smell. After burning, the ashes are dark brown lumps, which can be broken with fingers. The hand feel will also be different. Polyester has a rougher hand and nylon has a smoother hand. In addition, you can use your nails to scrape. After the nails are scraped, the obvious traces are tapen, and the less obvious traces are nylon, but this method is not as intuitive and easy to discern as the first method.

YYX specializes in the production, development and production of a variety of lanyard products, sublimation lanyard, face mask lanyard, silkscreen lanyard, Jacquard lanyard, short lanyard, special lanyard, etc... You can also print diy color LOGO, or arrange custom-made according to customer specifications and requirements . All materials used are environmentally friendly and non-toxic materials that are durable and washable, do not fade, do not ball, feel good, and are easy to adapt to the skin. Our company has a variety of printing technologies and can customize OEM production according to customer needs. Self-built silk screen, high frequency, tram, assembly, packaging and other process workshops to provide customers with the most effective supporting services

-

Such a beautiful keychain makes people love and hate!

Such a beautiful keychain makes people love and hate!If you are a designer, then lines like "Tune a little bit here", "Help me change t...

Do you like ?0

Read more -

Easy to carry Water Bottle Lanyards buying

Easy to carry Water Bottle Lanyards buying -

Advantages of using personalized printed Silicone Wristbands

Advantages of using personalized printed Silicone Wristbands -

The difference between nylon lanyard vs polyester lanyard - Yiyixing

The difference between nylon lanyard vs polyester lanyard - YiyixingWhat is Polyester Made Lanyards?

When it comes to <...

Do you like ?0

Read more -

Does Wear Cute lanyard can keep in a good mood?

Does Wear Cute lanyard can keep in a good mood?With the growth of age, girls are more and more inclined to adorabl...

Do you like ?0

Read more -

Why not choosing custom flight tags as a gift?

Why not choosing custom flight tags as a gift?Fabric key tag, made by embroidery or woven is one of our new appli...

Do you like ?0

Read more